Projects > Airlift

Airlift

Energy Sector Asset Inspections Automation

Airlift

Industry

Power, Oil and Gas Industry

Locations

Norway

Overview

Airlift

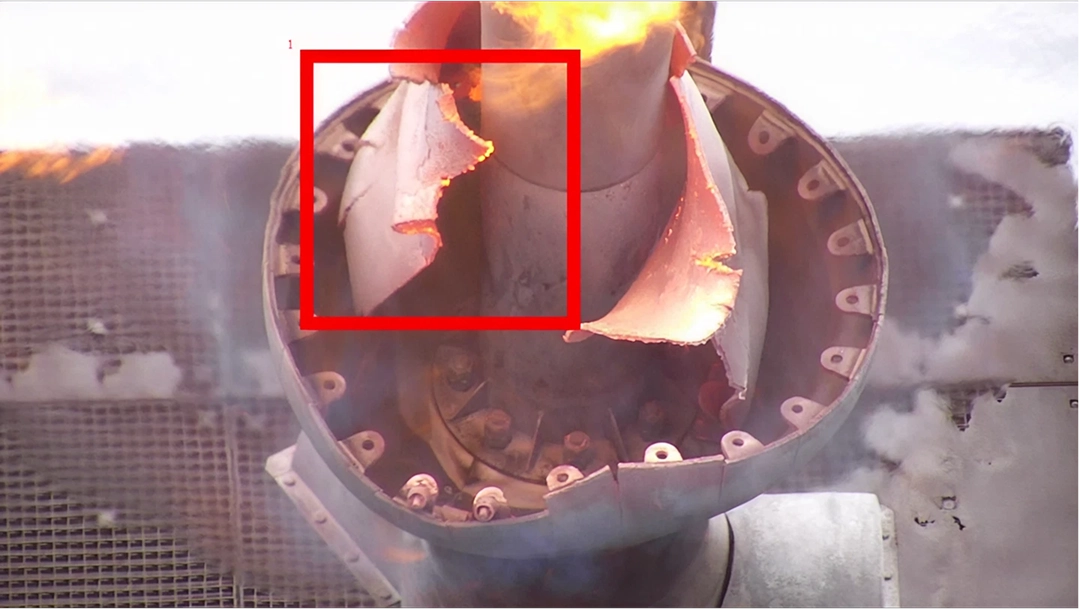

Our client is a pioneer in aerial inspections, specializing in periodic inspections of power grid lines and offshore oil rigs across North Europe and the North Sea. Using a combination of aerial platforms like helicopters and drones, their crews capture high-resolution visual and thermal imagery to monitor infrastructure health and preempt failures.

The Challenge

The inspections generated tens of thousands of images, each linked to critical infrastructure like power towers or oil rigs. Without a centralized, intelligent system, organizing, reviewing, and deriving insights from this massive dataset was inefficient in terms of time spent and fragmented. Teams relied on manual processes, making a comprehensive view difficult and slowing decision-making.

Our Solution

Airlift

We developed Airlift, a bespoke software platform designed specifically to manage and interpret large-scale aerial inspection data. Tailored for geo-tagged media and collaborative engineering workflows, Airlift offered an end-to-end solution:

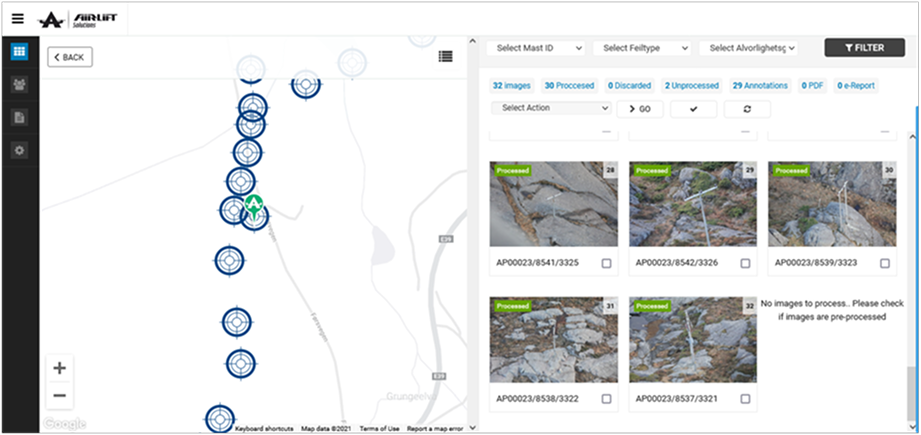

1. Geo-Tagged Image Mapping

Automatically indexed and overlaid tens of thousands of images on dynamic maps, linking them precisely to infrastructure components (e.g., towers, joints, rig elements).

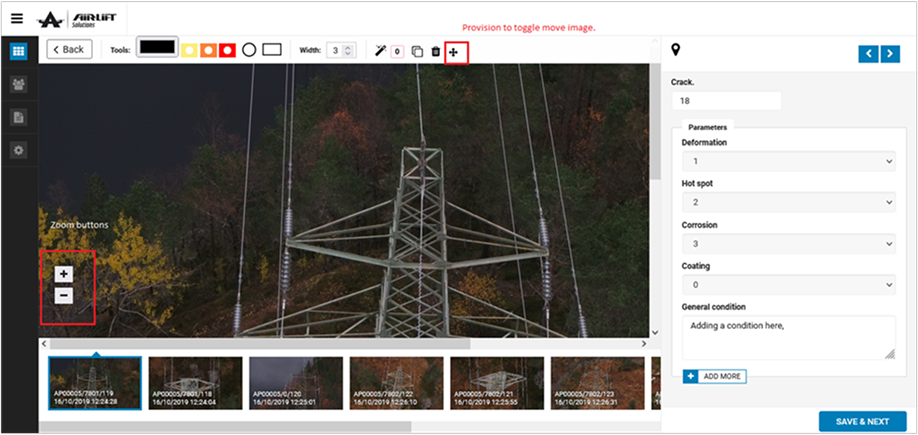

2. Visual & Thermal Layering

Seamless toggling between visual and thermal imagery, enabling deeper analysis of material health and performance under various conditions.

3. Time-Lapse Comparison Engine

Engineers could compare historical images of the same object, detecting stress patterns, corrosion, or other anomalies over time.

4. Automated Reporting

Generated detailed inspection reports with annotated findings, historical references, and recommended interventions—significantly cutting down turnaround time.

Impact

- Analysis and Reporting time Reduced by 60% through automation and image intelligence.

- Improved Engineering Accuracy, enabling early detection of material stress and fatigue.

- Enhanced Collaboration, with distributed teams working simultaneously on shared inspection data.

- Scalable Architecture, ready to accommodate growing datasets as aerial operations expanded.

Tech Stack

Backend

PHP

Frontend

React.JS PWA

Ads

Meta (Smart Bidding)

Why NASDOOR Trusts Team Inertia

“This system didn’t just digitize—it transformed how we maintain readiness. The team delivered defense-grade rigor with private-sector speed.”

— NASDO Commanding Officer

Key Outcomes

Faster servicing turnaround with automated workflows.

0

%

Audit compliance—every data change tracked and attributable.

0

%

Security incidents post-deployment (validated by Navy cyber teams).

0

Get in touch